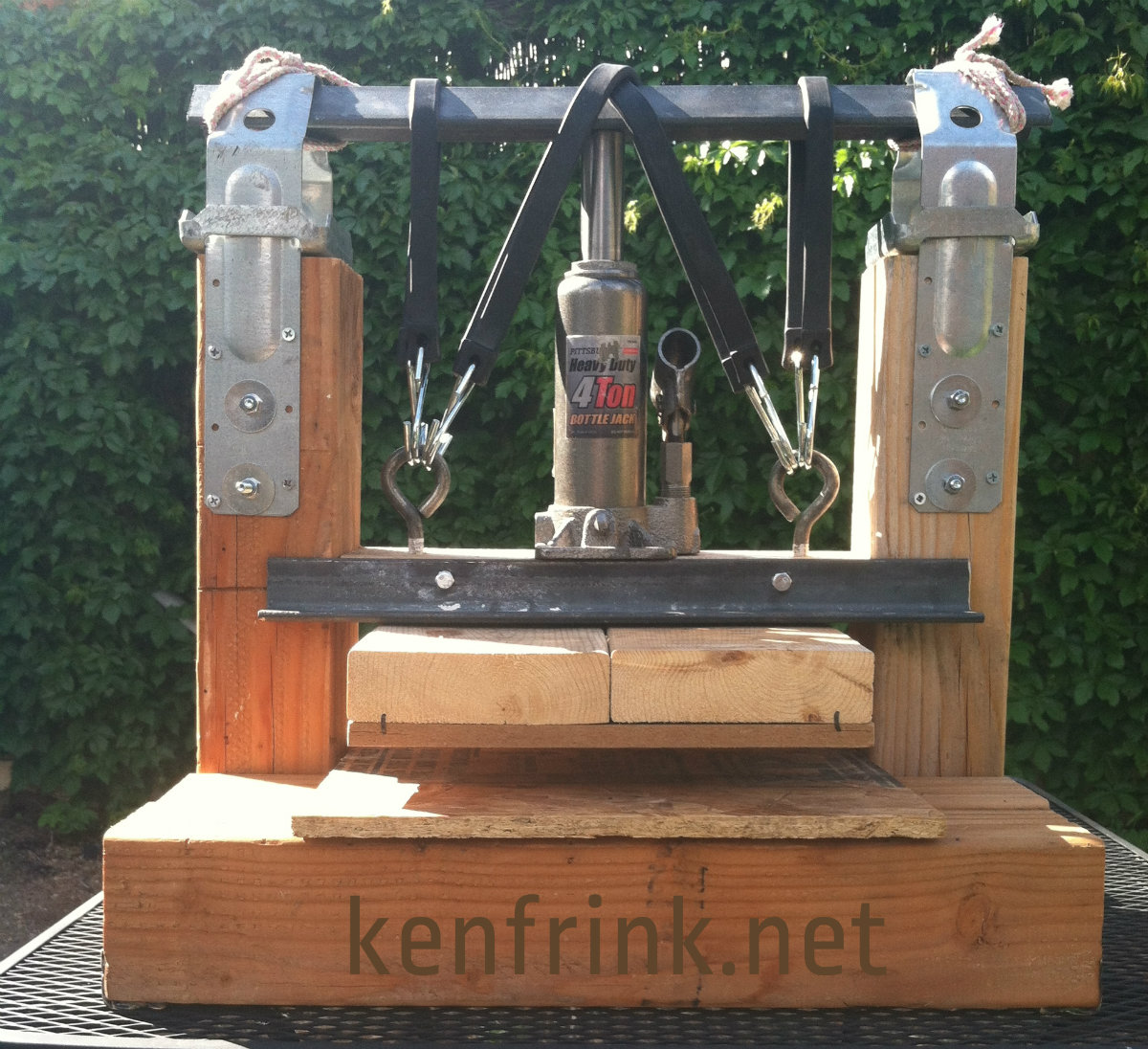

After seeing many similar designs online for building bottle jack presses, I decided to make my own. My scrap pile had enough metal and wood to build a small sturdy frame and I owned an extra bottle jack from a roof structure repair adventure. I couldn't resist.

From a heap of scraps, I built a new press for small relief printing projects. I've included a photo below. This is the beauty of the internet. A tinkerer here and there has always had a nice solution to a common problem. Because these people are not necessarily trying to make money off of their ideas, the ideas previously stopped in their workshops right where they were born. Now, a DIY design solution is easily shared with like-minded people...

I spent about $40 on hardware, stretchy straps, a drill bit, and a new grinder wheel. Exciting. It can accommodate 13" wide paper. The area that applies pressure is 11"x12". I think it would be easy to scale up a little. At some point there would be serious issues with even distribution of pressure.

Using an old hand towel instead of traditional felt blankets I got a nice test proof of flat black on wet paper. Not bad from a wonky OSB press bed, I'm ready to print.